Knowing the type of floor you are dealing with is the first step to a floor maintenance program. Understanding the unique characteristics of various hard floor types is crucial for effective floor maintenance. In this guide, we’ll explore resilient and non-resilient floors, outlining recommended cleaning solutions for each.

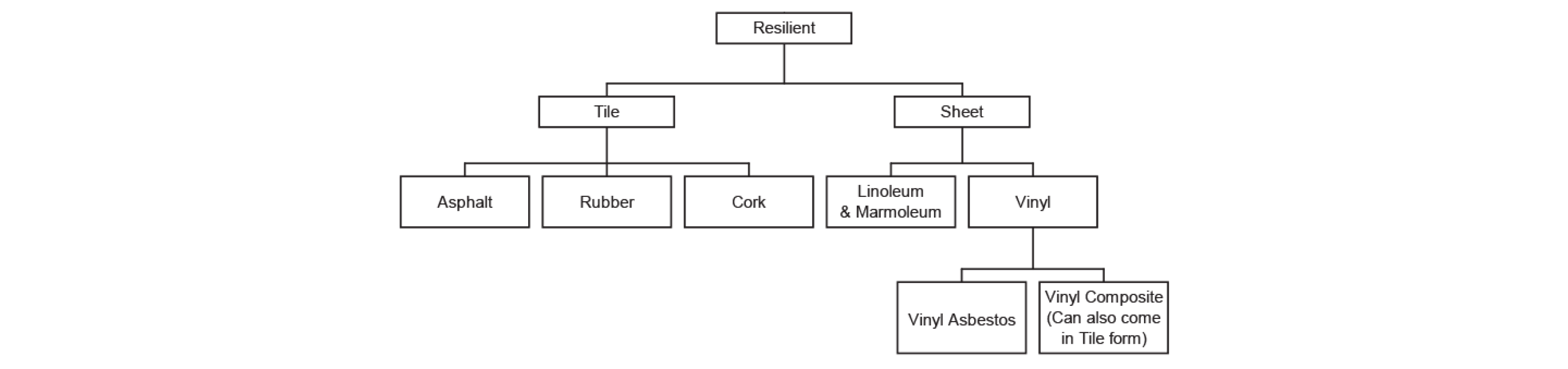

Resilient Floor

- Resilient floors are primarily composed of resins and/or polymers.

- They exhibit thermoplastic properties, allowing them to change form with variations in temperature.

- The material is pigmented or coloured, offering a range of design options for interior spaces.

- Generally, contain plasticisers and inorganic extenders to give hardness and density

1. Asphalt Floor (Synthetic floor tile)

Composition of Asphalt Floor:

- Man-made asbestos fibres, lime rock, mineral fillers, and colouring.

- Binder options: Asphalt (resulting in a darker colour) or a resin (yielding a lighter colour).

Properties of Asphalt Floor:

- Very durable

- Susceptible to damage from soap, harsh alkaline substances, solvents, and oils.

- Porous in nature. Water can loosen bindings between the tile and the floor. Requires caution with grit and water; trampled-in dirt diminishes floor brightness.

- Requires several layers of acrylic sealer.

- Polymer finish may cause powdering. Use water emulsion resin finish instead. Once it powders, it cannot buff back to original shine.

- Thermoplastic properties: Becomes brittle and prone to cracking when cold; becomes soft and can dent when hot.

Maintenance/ Cleaning Asphalt Floor:

- Use only synthetic liquid cleaners; avoid soap as it can emulsify components and weaken the tiles.

- Use minimal water for cleaning due to its porous properties, and promptly remove all water.

- Avoid solvents, solvent-type liquids, or oils, as they can break down the tile.

- Exercise caution with extreme hot or cold treatments due to its thermoplastic properties.

2. Rubber Floor (Natural or Synthetic)

Composition of Rubber Floor

- Contains rubber (natural or synthetic), minerals (e.g., clay, wax, oil), colouring, and sometimes asbestos.

Properties of Rubber Floor

- Mostly features marble patterns, shiny, flexible, and durable.

- Dense, smooth surface resists abrasion, warping, buckling, stains, mild acids, and mild alkalis.

- Non-porous, waterproof, and resists mould growth.

- Alkali, oil, grease, and solvent-resistant (if synthetic).

- Sun and air susceptible.

Maintenance/ Cleaning Rubber Floor

- Avoid prolonged use of alkaline or caustic cleaners; use a neutral cleaner (pH 7.0-8.0).

- Keep away from strong soap and alkali to prevent softening, stickiness, and subsequent brittleness.

- Avoid contact with solvents, oils, and grease, as they soften and swell tiles.

- Use a soft sealer and finish to prevent powdering, as rubber is soft.

3. Cork Floor

Properties of Cork Floor

- Not highly stain or dirt resistant.

- Cork easily absorbs water when mopped, allowing dirt to be tracked in.

- Difficult to apply sealers or finishes due to the pliable nature (cushion effect).

Maintenance/ Cleaning Cork Floor

- Dust mop frequently due to its porous property.

- Avoid excessive mopping; use minimal water due to its porous nature.

- Ultra High-speed finishes, being more pliable, adhere better.

4. Linoleum or Marmoleum Floor

Composition of Linoleum or Marmoleum Floor

- Natural, made of linseed oil, resins, colouring, ground cork or wood, pressed onto a burlap backing.

- Marmoleum is simply a linoleum produced with a marbled colour pattern.

Properties fo Linoleum or Marmoleum Floor

- Features colours and patterns that extend throughout, offering resilience superior to asphalt, vinyl asbestos, or wood, while also being more flexible than vinyl asbestos.

- Vulnerable to acids, strong alkalis, and water, it can become brittle, crack, or yellow when exposed to strong alkali and acid.

- Highly resistant to oil, grease, and water, with slip resistance comparable to vinyl asbestos, but not impervious to solvents.

Maintenance/ Cleaning Linoleum or Marmoleum Floor

- Sealer recommended with 2-3 coats, followed by 2-3 coats of finish.

- Avoid highly alkaline strippers to prevent yellowing.

- Scrub with a weak acid solution (e.g., vinegar) to remove discoloration; ensure no acid residue.

- Rinse with neutral cleaner.

5. Vinyl Floor

All vinyl comprises tough, flexible, chemically inert vinyl resins that are odourless and thermoplastic.

5.1 Vinyl Asbestos Floor

Composition of Vinyl Asbestos Floor

- Vinyl resin, plasticizers, asbestos fibres, mineral fillers, and pigment.

- Like Asphalt tile; crucial to distinguish for different maintenance.

- Distinguish by wetting a white cloth with turpentine and rubbing a dark tile; discoloration indicates asphalt.

Properties of Vinyl Asbestos Floor

- Less porous than asphalt.

- Excellent resistance to grease and oil.

- Outstanding wear and indentation resistance.

- Water and soap-resistant, suitable for bathrooms.

- High heat and moisture resistant; does not shrink or expand in the sun.

- Susceptible to low heat, leading to brittleness.

- Vinyl asbestos is harder than vinyl composite due to added asbestos as a hardening extender.

Maintenance/ Cleaning Vinyl Asbestos Floor

- Use plenty of water when stripping to avoid releasing asbestos fibres into the air.

- Buffing is possible with a good base coat of finish and a non-aggressive buffing pad.

- Minimize scrub and strip cycles to prevent irregularities on the porous surface.

- Synthetic travertine tile (a vinyl asbestos offshoot) with surface irregularities benefits from brushing over buffing. For severe dirt, resoak, scrub, vacuum, flood rinse, and vacuum again.

5.2 Vinyl Composite Floor

Composition of Vinyl Composite Floor

- Similar to vinyl asbestos but without asbestos.

- Pure and homogeneous, consisting of vinyl resins, plasticisers, and sometimes stabilised with metallic chips.

- Pigment used for colour, typically with a transparent wear coating of polyurethane, acrylic, or vinyl.

Properties of Vinyl Composite Floor

- Generally, more durable and safer than asbestos.

- Contains a release agent (silicone, paraffin wax, or a combination) to prevent tiles from sticking together when stored.

Maintenance/ Cleaning Vinyl Composite Floor

- Remove the release agent before applying maintenance coatings to prevent adhesion and poor levelling.

- Coatings do not adhere well to wax, as they bead similarly to water on wax.

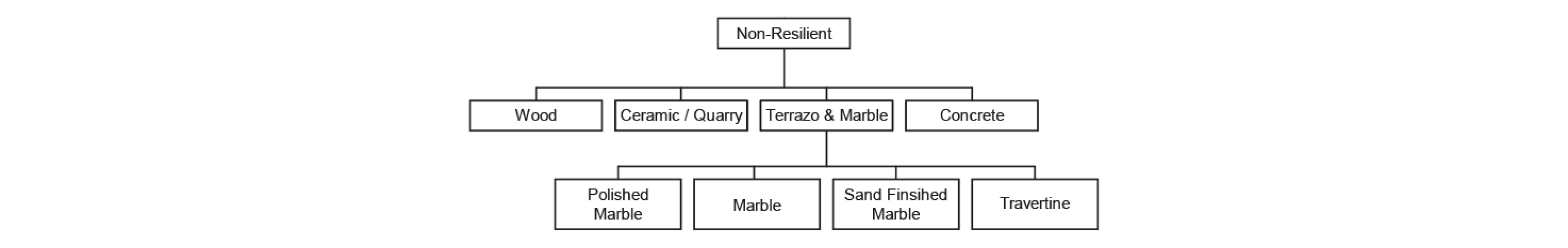

Non-Resilient Floors

Compared to resilient flooring, non-resilient flooring is characterized by being:

- More durable

- More resistant to stains

- More resistant to solvents

- More resistant to acids and alkalis

- Can be either manmade or natural.

6. Hardwood Floor

Maintenance/ Cleaning Hardwood Floor

- Sweep the wood floor daily with a dry, oil-free dust mop to remove dust, grit, sand, and abrasive particles.

- Periodically dry buff the surface using a fine number 0 grade steel wool pad on a rotary-type electric buffing machine to eliminate scuff marks and restore the original lustre. Sweep the floor clean after buffing to remove dirt and steel wool particles.

- Wipe spillages immediately to prevent absorption.

- Remove marks and discoloration using a finish rejuvenator, applied by a soft cloth, lambswool applicator, or dusting mop.

- Periodically clean and refinish waxed floors. Use a wax-removing solvent-type cleaner with a fine number 0 grade steel wool pad, wiping the surface dry to remove dissolved dirt and traffic film. Follow with a fresh coat of paste wax or liquid spirit-based finish/wax.

- Avoid using a scrubbing machine with soaps or strong detergents, as they may damage the floor.

- Coatings can be applied over polyurethane. Ensure a neutral pH before proceeding with coating, as with all flooring.

7. Ceramic Floor, Quarry Tile Floor and Brick Floor

Maintenance/ Cleaning Ceramic Floor, Quarry Tile Floor and Brick Floor

- Use the same precautions as with terrazzo and marble.

- Usually don’t need sealing, except for mortar/grout, which can stain and hold odours.

- Use a water-based sealer as on marble or terrazzo.

- Use a synthetic detergent cleaner with a pH less than 10.0.

- Use a treated dust mop for daily sweeping, ensuring it doesn’t leave an oil film on the floor.

8. Marble & Terrazzo

8.1 Marble and Marble Derivatives

Types of Marble:

- Polished marble – Used extensively for walls and decorative purposes, seldom for floors.

- Honed Marble – Widely used for floors, distinguished by a dull smooth surface with little light reflection.

- Sand-finished marble – Coarser surface than honed marble, mainly used for floors and platforms.

- Travertine – Recognizable by small pits in its ‘tannish’ coloured surface.

Properties of Marble

- Polished marble is highly impervious to water, causing adhesion problems for sealers and finishes.

- Scratches easily, even with stripping and burnishing pads.

Maintenance/Cleaning Marble

- Travertine requires regular cleaning and maintenance, while other types of marble should be treated and maintained like terrazzo.

- Always use a neutral synthetic cleaner.

- Use penetrating sealers for good adhesion, as they fill pits in marble.

8.2 Terrazzo & Terrazite

Composition of Terrazzo & Terrazite

- Good quality terrazzo is 70% marble chip, 30% cement mix (Terrazzo) or resin mix for Terrazite.

- Marble is composed of calcium carbonate.

- Can be coloured.

Properties of Terrazzo & Terrazite

- Susceptible to chemicals.

- Not highly porous.

- Scratches easily.

Maintenance/ Cleaning Terrazzo & Terrazite

- Calcium carbonate is not very resistant to chemicals, especially acids and alkalis.

- Acid causes defacing or pitting of the floor.

- Alkali causes the decomposition of calcium carbonate.

- Cleaner must have a pH less than 10.0.

- Unsealed terrazzo/Terrazite can result in a cloudy surface when exposed to hard water.

- Terrazite is non-porous and absorbs very little, while Terrazzo is porous and absorbs liquid, causing staining and lack of adhesion without the right sealer.

- Always use a sealer and finish with Terrazzo.

- Requires sealing and coating to prevent dusting (natural tendency to dust with age). Apply 2 coats of seal and 2–3 coats of finish.

- Subject to abrasion; avoid crystalline cleaners, soaps, scrubbing powders with water-soluble, inorganic salts, and crystallizing salts.

- Avoid oily compounds as they cause stains and discoloration.

- Avoid steel wool; particles left on the floor can cause rust stains.

9. Concrete

Composition of Concrete

- An alkaline material composed of water, Portland cement, sand, and gravel.

- Can be coloured.

Properties of Concrete

- If uncured, concrete is very porous and susceptible to penetration of damaging moisture and stains.

- Cured concrete hardens due to a chemical reaction between cement and water.

- Promotion of curing can be done by covering with an inch of water, strips of burlap, or craft paper, typically using a polymeric concrete curing aid.

- This curing aid forms a thin membrane over the floor to retard water evaporation, resulting in a more effective reaction and complete curing.

- Curing prevents the penetration of greases or adhesion of paint, soil, and plaster, and prevents dusting or blooming.

Maintenance/ Cleaning Concrete

- After curing, the floor should be scrubbed, cleaned, and sealed with a concrete sealer.

- Sealing improves appearance, aids in surface gloss, seals concrete pores, and prevents ingraining of soils.

- Lay 2 coats of seal and 2–3 coats of finish for optimal protection.