Maintaining clean commercial floors requires dedication and expertise. While floor cleaning and floor restoration processes may seem easy, lots of things can go wrong, making things frustrating and disappointing. This guide will help cleaning professionals by showing them the most common problems that happen when fixing up floors, what might be causing them, and what they can do to get the best results. Most floor care problems are caused by improper product use. For example, if a finish is not applied properly, problems can arise such as powdering (poor adherence), loss of durability and poor gloss.

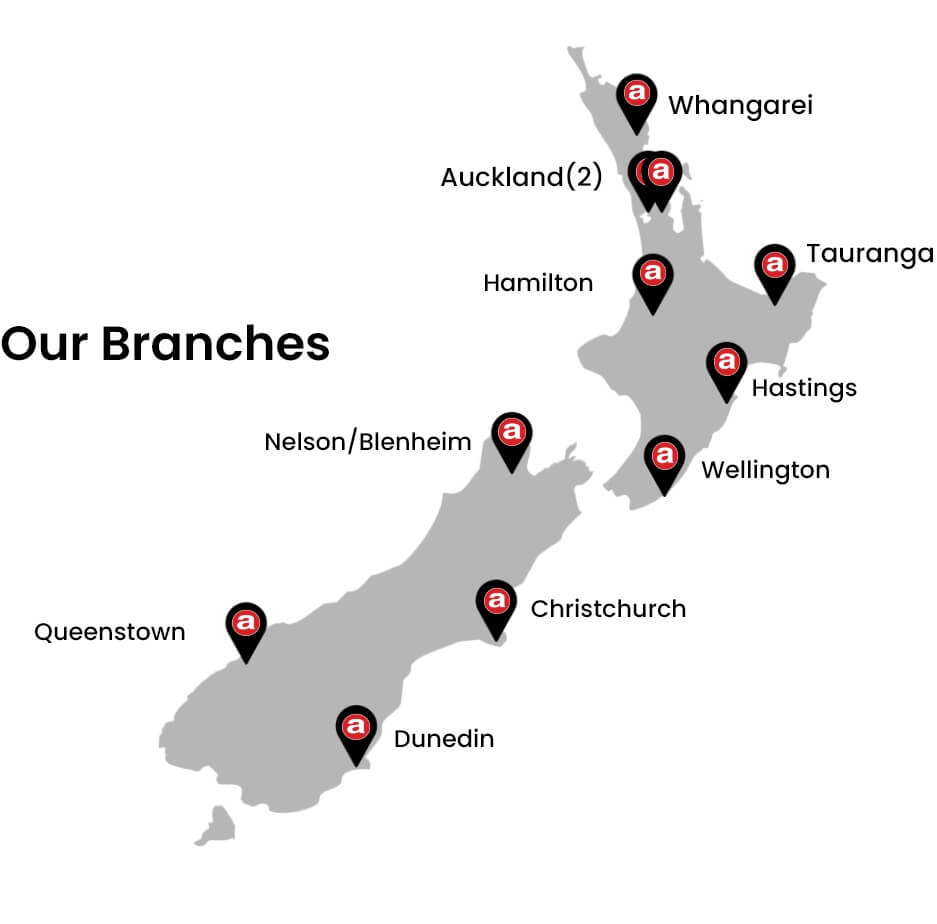

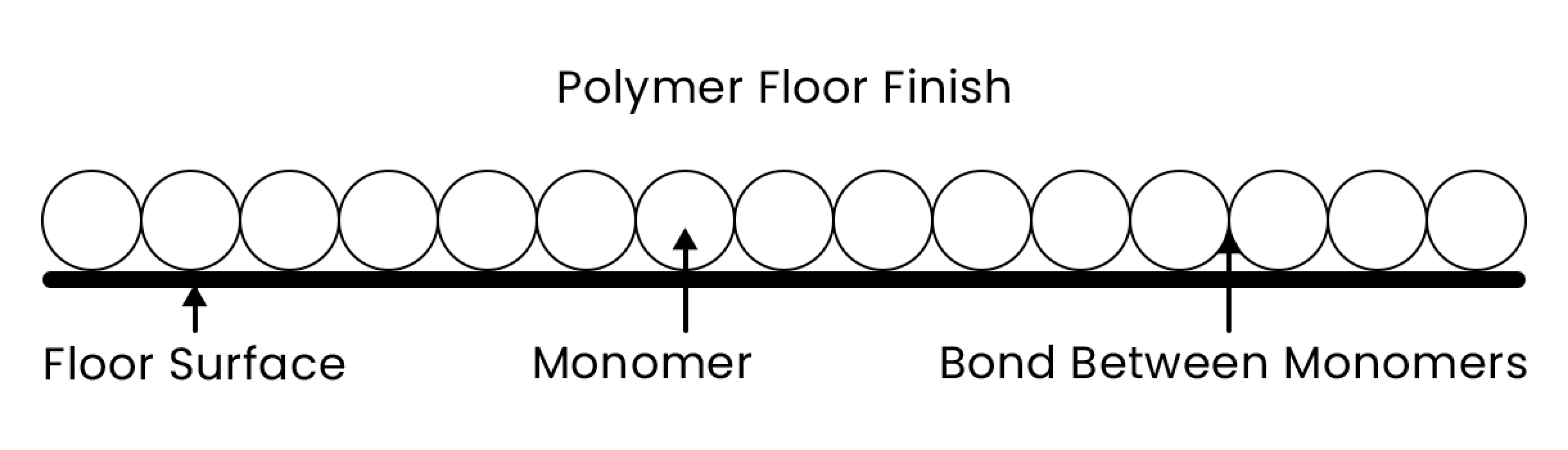

At the heart of many of these issues lies the critical concept of levelling, the even distribution of finish monomers across the surface. This crucial step ensures proper adherence, preventing swirling and streaking, and ultimately contributing to the overall quality and lifespan of your floors.

Here are key factors contributing to improper levelling:

- Not Enough Drying Time: If you don’t wait long enough between coats, the mop can drag the finish around, making it uneven and streaky.

- High Humidity: When it’s humid, the solvents in the finish dry quickly, but the water takes longer. This also makes the finish dry unevenly.

- Low Humidity: When it’s dry, the water in the finish dries quickly, but the solvents take longer. Again, this makes the finish dry unevenly.

- Forced Drying: If you try to dry the finish too quickly with fans or heat, it can dry unevenly and look bad.

1. Floor Finish is too tacky or sticky

- Too Thick Application: Applying the finish too thick can result in a sticky feel. Ensure a smooth and even application.

- Insufficient Drying Time: Allow adequate drying time between coats (20-30 minutes). High or low humidity may extend drying time.

- Improper Restorer Application: Dilute the restorer correctly and avoid frequent applications to prevent a sticky residue.

- Delayed Burnishing: Burnish the restorer promptly after application to avoid softening the finish.

- Incomplete Floor Rinsing: Thoroughly rinse the floor before applying the finish to prevent stickiness.

- Disinfectant Misuse: Be cautious with disinfectants; misuse can affect the finish. Follow recommended guidelines.

- Finish Separation: Shake or stir the finish before use, especially if exposed to prolonged heat.

- Contamination of Finish or Sealer: Ensure the finish or sealer is not contaminated to maintain a proper finish.

- Incompatible Chemicals: Stick to one manufacturer’s system to avoid issues with incompatible chemicals.

2. Occurrence of Swirls or Scratches while Applying Floor Finish

- Aggressive Pad Use: Avoid using a pad that is too aggressive for cleaning or burnishing to prevent swirls or scratches.

- Dirty Pad: Clean dirty pads with a wire brush or by spraying off build-up in a deep sink. Hang them up to dry.

- Dirty or Sandy Floor: Ensure the floor is clean and free of sand to prevent scratches during finishing.

- Improper Restorer Dilution: Dilute the restorer correctly; underuse or overuse can cause swirls.

- Excessive Finish Application: Apply finish in thin layers to prevent swirls caused by excessive re-coating.

- Incomplete Drying Before Burnishing: Allow the finish to completely dry before burnishing to avoid swirls. Shake the finish before use.

- Excessive Pad Pressure: Avoid applying too much pressure when using the pad to prevent swirls or scratches.

- Residue from Treated Dust Mops: Be cautious of residue left by treated dust mops; clean or replace them regularly.

- Incomplete Floor Cleaning and Neutralising: Properly clean and neutralise the floor after stripping to prevent swirls in the finish.

3. Discoloured Floor Finish

- Incomplete Floor Rinsing: Ensure proper rinsing after stripping; A floor that is too alkaline or too acidic can cause finish to discolour. Change rinse water frequently and wring out the mop thoroughly.

- Residue from Stripping: Check for any remaining finish after stripping by scraping the floor with a fingernail. If residue is present, re-strip.

- Dirty Mop and Bucket: Use a clean mop and bucket for finish application. Avoid using finish from the bottom of the bucket, as dirt settles there. Rinse the bucket between uses – stripper residue in finish bucket will cause finish problems.

- Poor Maintenance: Never apply new finish over old finish that has not been cleaned on a regular basis. This will cause finish to turn dark.

- Excessive Finish and Infrequent Scrubbing: Avoid applying too much finish and ensure regular scrubbing to prevent discoloration.

- Overuse or Strong Concentration of Restorer: Use the restorer at the correct frequency and dilution rate to prevent discoloration.

- Ground-in Dirt, Sand, and Grit: Dirt sand and grit are ground into the floor. Clean the floor before applying the finish.

- Residue from Untreated Dust Mops: Regularly clean or replace untreated dust mops to avoid residue that can cause discoloration.

- Incorrect Concentration of Neutral Cleaner or Disinfectant: Ensure the correct concentration of neutral cleaner or disinfectant to prevent floor finish discoloration.

4. Hazy or Cloudy Floor Finish

- Inadequate Drying Time: Allow sufficient drying time between finish coats to prevent haziness or cloudiness.

- Excessive Coat Thickness: Apply thin and even coats to avoid a hazy finish.

- Too Many Coats in a Day: Limit the number of coats applied in one day to prevent cloudiness.

- Excessive Cleaner in Dilution: Use the correct amount of cleaner in dilution to avoid haze.

- Hot Water for Cleaning: Avoid using hot water for cleaning, as it can contribute to a cloudy finish.

- Aggressive Pads: Use less aggressive pads to prevent haze during maintenance.

- Buffing/Burnishing Solution: Try buffing or burnishing to remove haze. If unsuccessful, consider stripping and re-coating.

5. Floor Edge Build Up and Discolouration

- Poor Maintenance of Edges: Pay extra attention to edges and corners during maintenance, where machines might miss. Ensure thorough cleaning, and manually scrub corners if needed during stripping.

- Finish Too Thick on the Edges: When re-coating areas of high traffic, stay away from edges. Burnishing will blend new finish in traffic lanes and old finish near edges together.

- Restorer Application Near Edges: Apply restorer only to traffic areas, avoiding application too close to edges to prevent discoloration and build-up.

6. Whitening of Asphalt Floor Tile

- Use of Alkaline Cleaner: Avoid using hot or even mild alkaline cleaners, as they can cause whitening of asphalt tiles.

7. Streaks in Floor Finish

- Re-coating Before Drying: Streaks occur due to re-coating before the prior coat is dry. To fix it, burnish it out. If unsuccessful, strip, rinse well, and apply new finish.

- Application on Unstripped New Tile: If finish is applied on new tile without stripping the factory finish, strip it, rinse well, and apply new finish.

- Dirty Mop or Equipment: Ensure mop and equipment are clean to prevent streaks.

- Frozen Floor Finish: Replace frozen finish, strip, rinse well with neutral cleaner and water, and apply new finish.

- Poor Floor Maintenance: If streaks result from improper floor maintenance, strip, rinse well, and apply new finish.

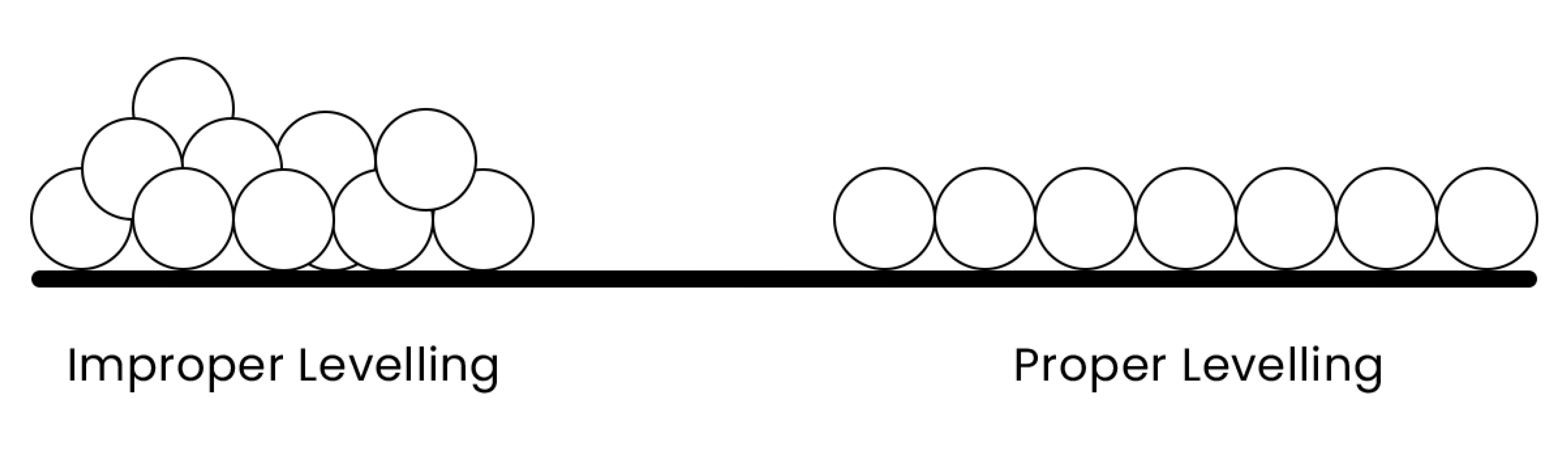

- Extremely Porous Floor Surface: If the floor surface is highly porous, strip it, rinse well, and apply new finish to address streaks.

8. Circular Blemishes or “fish eyes” on Floor Finish

- Thin Finish Application: Applying the finish too thinly can cause it to dry too quickly and result in circular blemishes. Ensure a proper and even application.

- Excessive Coating Thickness: Applying the coating too heavily can lead to circular blemishes. Apply the finish in moderate, even layers.

- Agitation During Pouring: Avoid agitating the finish when pouring it into the bucket, as this can introduce air bubbles. Pour gently to prevent “fish eyes.”

- Contaminated Bucket or Mop: Ensure the bucket and mop are free of contaminants that can cause circular blemishes. Keep equipment clean for a smooth finish application.

9. Powdering / Poor Adhesion of Floor Finish

- Aggressive Pad Use: Avoid using overly aggressive pads that can lead to powdering and poor adhesion.

- Dirty Pad: Ensure the pad is clean to prevent dirt particles from affecting finish adhesion.

- Strong or Frequent Restorer/Maintainer Use: Use the correct dilution of restorer/maintainer to prevent overuse or excessive strength, which can contribute to powdering.

- Unsealed Floor Before Finish Application: Seal the floor before applying finish to ensure proper adhesion and prevent powdering.

- Application on Unstripped New Tile: Strip and rinse new tile before applying finish to avoid issues with the factory finish.

- Residue from Treated Dust Mops: Regularly clean or replace treated dust mops to prevent residue that may interfere with finish adhesion.

- Incomplete Floor Cleaning and Neutralising in Stripping: Properly clean, neutralise, and rinse the floor during stripping to prevent poor adhesion.

- Re-coating Before Drying: Allow adequate drying time between finish coats to ensure proper adhesion.

- Insufficient Drying Time or Forced Drying: Ensure proper drying time and avoid forced drying methods that may compromise finish adhesion.

- Thin Coat of Finish: Apply a sufficient and even coat of finish to enhance adhesion.

- Inadequate Removal of Old Finish: Thoroughly remove old finish residue to allow proper adhesion of the new finish.

- Mismatch of Buffability: Avoid using a non-buffable finish over a buffable one to prevent compatibility issues.

- Hot Solution or High Alkaline Cleaner: Refrain from cleaning the floor with hot solutions or high alkaline cleaners, as they can affect finish adhesion.

10. Lack of Water Resistance of Floor

- Insufficient Rinsing of Cleaner: Ensure thorough rinsing of cleaner before applying finish to prevent a lack of water resistance.

- Use of Inferior Finish: Choose a high-quality finish to ensure proper water resistance on the floor.

- Mop Containing Stripper: Avoid using a mop that has previously been in contact with a stripper, as it can compromise water resistance.

11. No Floor Shine

- Incomplete Rinsing of Stripping Solution: Ensure thorough rinsing of the floor after using a stripping solution to avoid dullness.

- Thin Application of Finish: Apply finish in an adequate thickness to fill all pores on the floor surface. A thin application can result in a lack of shine.

- Contamination in Finish: Use clean equipment and avoid pouring unused finish back into the container to prevent contamination.

- Aggressive Burnishing Pad: Use a less aggressive burnishing pad to avoid dullness during the polishing process.

- Dirty Burnishing Pad: Keep the burnishing pad clean to achieve a shiny finish.

- Sand, Dirt, or Grit on Floor: Clean the floor thoroughly to remove excess sand, dirt, or grit, which can cause an uneven surface and reduce shine.

- Brittle Finish: Apply a restorer product regularly before burnishing to maintain the flexibility of the finish and enhance shine.

12. Slippery Floors

- Oil or Silicone Deposits from Treated Mops: Avoid using treated mops that deposit oil or silicone, as they can make the floor slippery.

- Spills of Lubricants, Oils, Polishes, or Other Substances: Quickly clean up spills of lubricants, oils, polishes, or similar substances to prevent slippery floors.

- Tracked-in Water from Outside: Be cautious of water being tracked in from outside, as it can contribute to slippery floors.

- Insufficient Burnishing: Regularly burnish the floor to restore slip-resistant properties and enhance safety.

- Inadequate Finish Application: Ensure enough finish is applied to maintain slip resistance. Recoat the floor when it no longer responds to restorer.

- Inferior Maintainer or Cleaner: Choose a high-quality maintainer or cleaner to avoid issues with floor slipperiness.

13. Soft Floor Finish/Floor Finish getting Scratched

- Infrequent Burnishing: Burnish the floor regularly to harden the finish and reduce susceptibility to scratching.

- Tracked-in Dirt, Grit, and Sand: Minimize tracked-in dirt, grit, and sand to protect the finish from being easily scratched.

- Incorrect Floor Pads: Use the appropriate floor pads to prevent easily scratching the finish.

- Inappropriate Floor Finish: Choose the right floor finish based on floor type, traffic, soiling, and maintenance frequency to prevent a soft finish.

- Undiluted Restorer: Dilute the restorer properly to avoid issues with a soft finish.

- Dirty Floor Pads: Keep floor pads clean to prevent scratching during maintenance activities.