Maintaining hard floors involves a strategic approach, including the use of specialised chemicals and machines.

Floor Cleaning Chemicals

A Chemical Floor Care System consists of 5 elements:

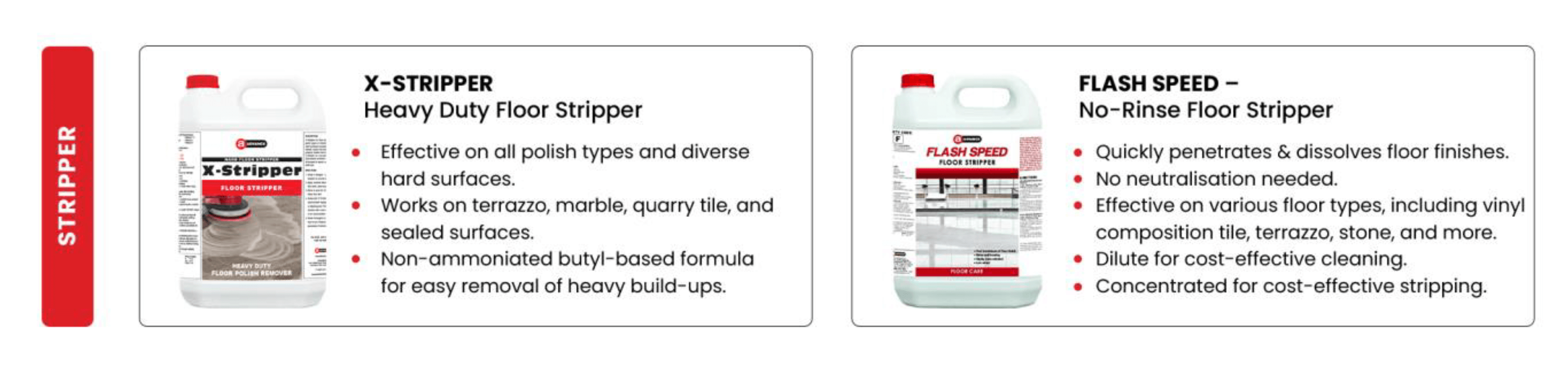

1. Stripper: Remove old and damaged floor finish.

2. Sealer: Add a protective coating, filling pores and providing a level surface.

3. Finish: Enhance appearance and add an extra layer of protection.

4. Restorer: Repair damage and maintain a high gloss appearance.

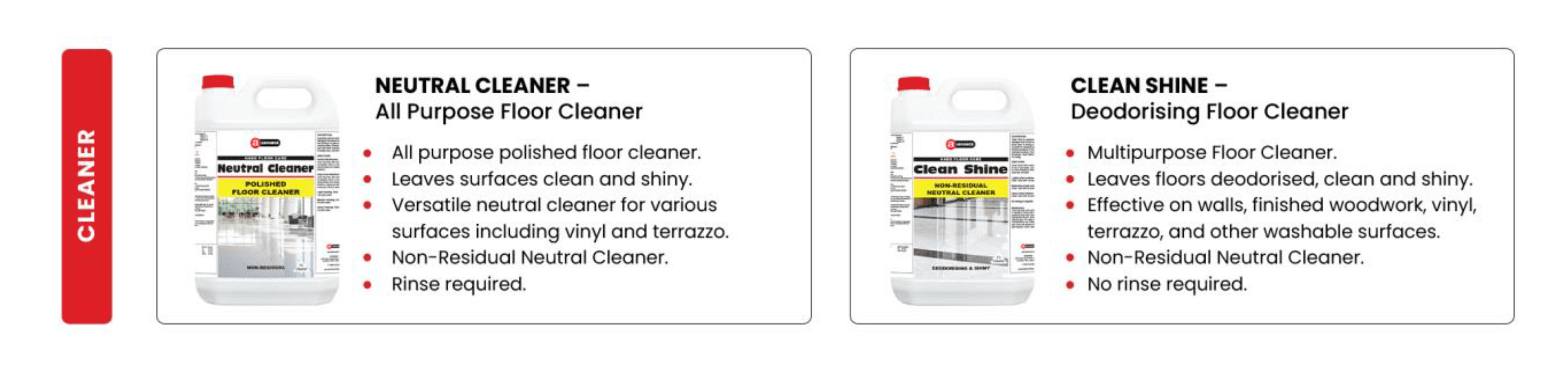

5. Cleaner: Regular cleaning to prevent damage and reduce the frequency of stripping and resealing.

Floors should be cleaned regularly to keep them clean, and to prevent tracked in dirt from embedding in the polish surface.

Floors should be cleaned regularly to keep them clean, and to prevent tracked in dirt from embedding in the polish surface.

Understanding pH in Floor Cleaning

pH is a measure of acidity or alkalinity on a scale from 0 to 14. Neutral is pH 7, below 7 is acidic, and above 7 is alkaline. Most human-generated dirt is slightly acidic (pH 5.5 – 7). To clean acid, use an alkali, but avoid using a higher alkali value than necessary. Always “neutralise to clean” to prevent floor damage.

Common products like sealers, finishes, and restorers usually have a pH around 8.5. Neutral cleaners have a pH of 7, while strippers for old finishes have a high alkaline value. Following these pH principles ensures effective cleaning while safeguarding the floor.

Do’s and Don’ts with Floor Chemicals

- Never use a dirty mop for applying floor care products.

- Never use oil treated sweeping mops for applying floor care products.

- Never mix and match different brand chemical products.

- Never pour unused sealer or finish back into the container.

- Never use a lower dilution ratio than is recommended.

- Never re-coat before the previous coat is dry.

- Never exceed the recommended number of coats.

- Never burnish without cleaning the floor first.

- Always rinse new cotton mops for polish application

Floor Finishes

Two Types of Floor Finishes

Wax Polishes: Containing various natural and/or synthetic waxes, wax polishes fall into the first category. The advantage is, it can endure more sand and dirt without wearing off. However, they may scuff and mark more easily due to their softer composition.

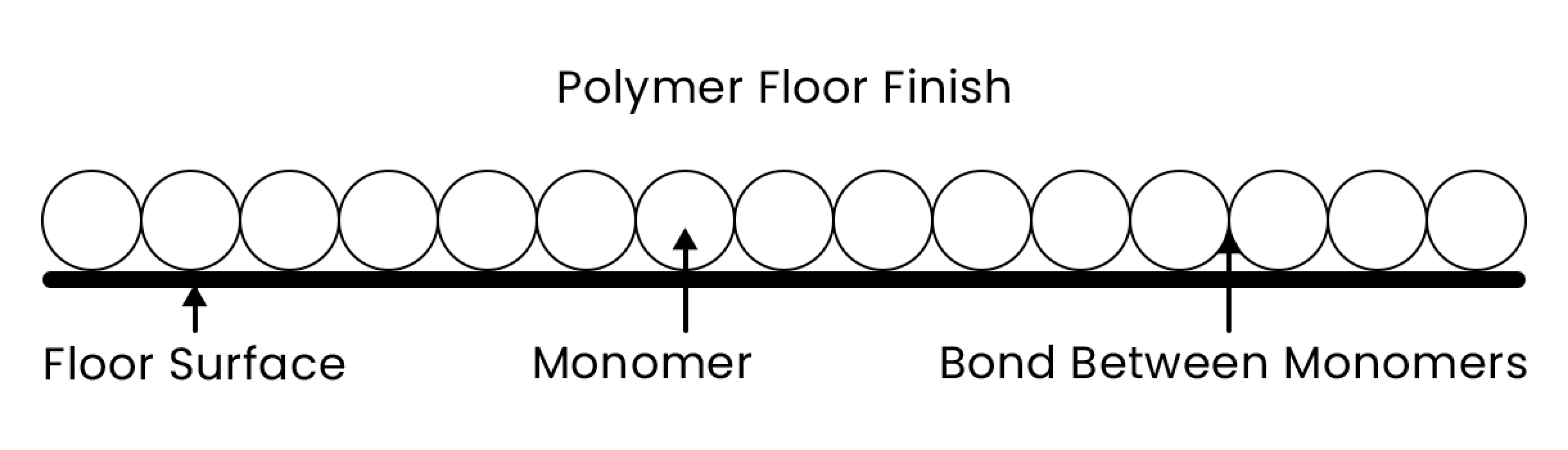

Polymer Finishes: This category includes finishes containing polymers, acrylics, styrene, polyethylene, and other synthetic or natural polymers.

What are polymers? Polymers are long chain molecules. They are made up of monomers bound together by chemical bonds.

Chemical Components of Finish

Volatile Components: These elements, like water or solvents, aid in film formation, shaping, and curing during the application of finishes. However, they evaporate during the drying process and do not remain on the floor surface.

Non-volatile Components: These are the solids in the finish that stay on the floor surface once the finish has dried. They contribute to the finish’s lasting effect and overall resilience.

Floor finishes can be one of the following:

Buffable Floor Finish:

- Dry to a pliable glossy film enhanced by buffing.

- Recommended machine speed: 175rpm to 450rpm (low speed).

- Can be dry buffed for scuff marks, top scrubbed, re-coated, and dry buffed in high-traffic areas. Typically contain over 60% wax.

Non-Buffable Floor Finish:

- Dry to a hard gloss, resistant to scuffing, black marking, and dirt embedment.

- Recommended machine speed: 175rpm to 750rpm (low speed) and 1000rpm to 1500rpm (high speed).

- Maintained by wet mopping and spray buffing.

- Traffic areas showing wear can be top scrubbed and re-coated.

- Generally, contain 25% wax.

Ultra-High Speed (UHS) Floor Finish:

- Combine features of buffable and non-buffable formulas.

- Contain 25-60% wax.

- Recommended machine speed: 2000rpm to 2500rpm (ultra-high speed).

- Faster machines reduce the time needed for a high gloss.

Floor Stripper

High pH Stripper: Strippers, often high in alkalinity, require neutralising after use to prevent floor damage.

No-Rinse Stripper: Reduces rinse requirement, saving time and labour. The advantages of a “No rinse” stripper are labour and time savings. These strippers work by dissolving the floor sealer and finish, making the removal faster and easier. There is generally, less residue left.

“No rinse” strippers contain solvents. This means that they are not as alkaline as other strippers. The advantage of this is that after the sludge of old sealer and finish are removed, the floor does not have to be rinsed several times to neutralise. Advance recommends that the floor be damp mopped once however, to remove any residue that is left.

The disadvantages are that solvents are unpleasant to work with (due to their strong smell). Also, they cannot be used on all floor types. Solvents are not suitable for Asphalt, rubber or asbestos, and may also weaken the adhesives that bind tiles.

Three crucial performance factors determine the effectiveness of a stripper:

- Wetting: A quality wetting stripper ensures uniform wetting across the entire surface for thorough stripping.

- Penetration: An effective penetrating product swiftly and completely penetrates through the finish down to the flooring.

- Emulsification: A successful emulsifying stripper breaks down the bonds between the monomers of a finish, facilitating easy removal by the floor machine.

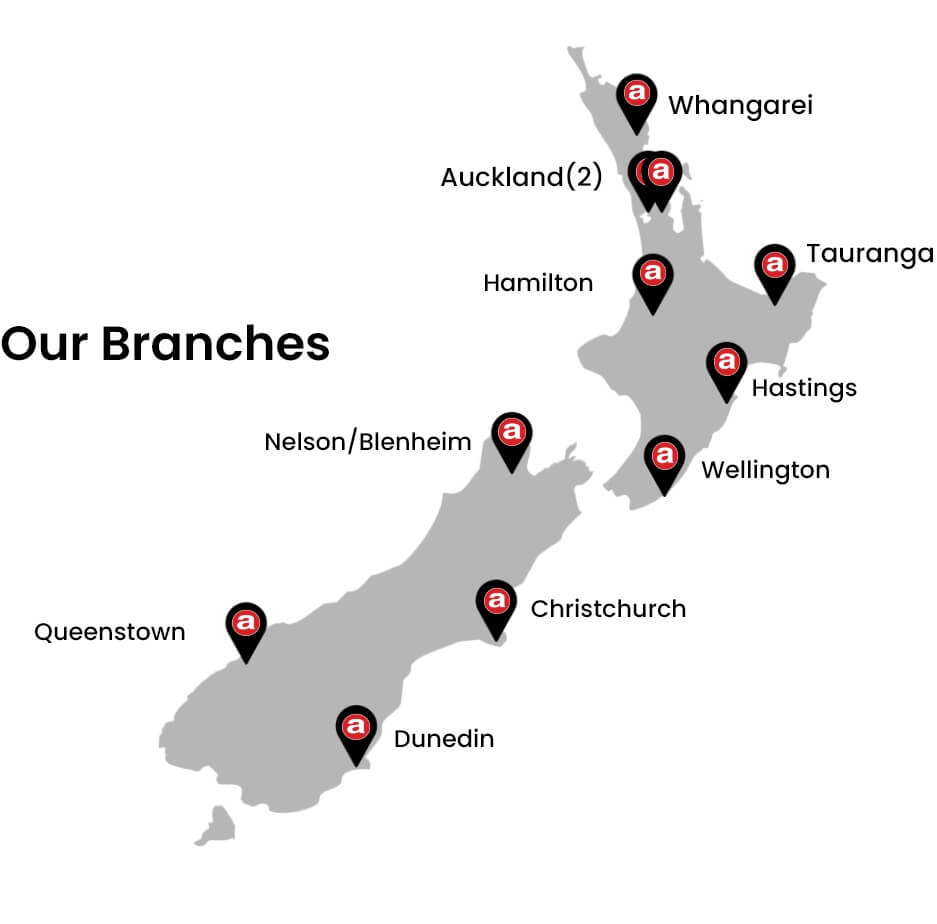

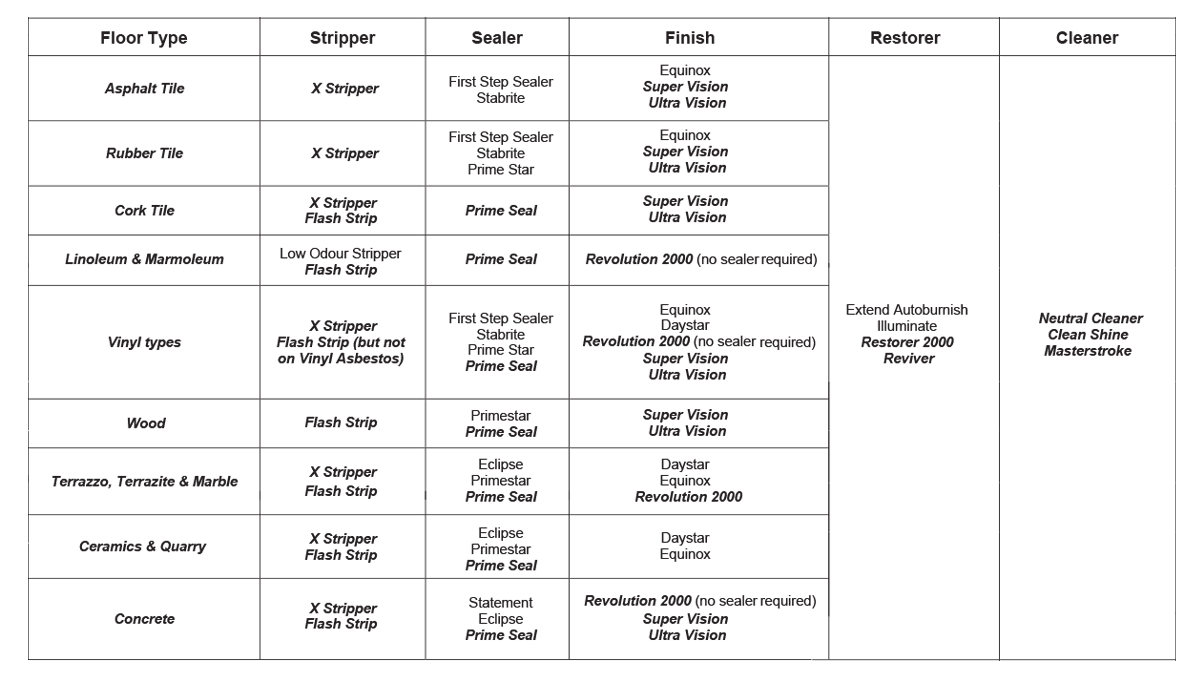

Recommend Advance Floor Cleaning chemicals for various types of floors and applications, including stripping, sealing, finishing, restoring, and general cleaning.

Floor Care Machines and Pads

Automatic scrubbers and burnishers maximise cost effectiveness. In selecting the best equipment for your needs, there are several important factors to consider, including:

- Size of the floor area

- Number and type of obstructions

- Type of facility

- Traffic conditions

- Time of day maintenance will be performed (for noise and access reasons)

- Time available for maintenance

- Available power sources

- Level of desired maintenance

- Budget constraints

- Safety

Floor Care Machines

Choosing the right floor cleaning equipment is crucial for proper floor care. Among the available options—floor scrubbers, polishers, and burnishers—each serves a distinct purpose.

Floor Scrubbers:

- RPM (Revolutions Per Minute): Lowest RPM among the three types.

- Function: Used for quickly cleaning large areas.

- Finish: Does not generate a polished finish.

- Heat Generation: Low RPM prevents generating enough heat to melt floor sealer and hide scratches.

- Varieties: Come in various sizes and shapes with options like rotating brushes, pads, and contra-rotating brush heads.

- Operation: Some only perform scrubbing, while others combine scrubbing with spraying cleaning solution and suction in one motion.

Floor Polishers:

- RPM: Faster than floor scrubbers, usually around 400 RPM.

- Function: Does not clean floors but provides a glossy, polished appearance.

- Best Suited For: Light to medium traffic areas, such as those in office buildings or schools.

- Ideal Surfaces: Works best on wood or vinyl floors.

Floor Burnishers:

- RPM: Most powerful, rotating at a speed of 1200 to 1800 RPM.

- Function: Used on floors previously sealed with a hard-wearing sealer.

- Ideal Environments: Suitable for areas with constant, high foot traffic like grocery stores and shopping centres.

- Finish: When used properly, burnishers create a super high-gloss finish.

Burnishers come in three types: propane, battery, and electric, each offering distinct features and benefits.

Propane:

-

- Best combination of pad pressure and speed.

- Increases productivity and delivers a superior “wet-look” finish.

- Cordless, lightweight, and highly mobile.

- Operates continuously for extended periods.

- High power, suitable for covering large areas quickly.

- Noisy and not suitable for small, enclosed areas due to fumes.

Battery:

-

- Mobile and suitable for various settings, including hospitals and nursing homes.

- Quiet operation.

- Requires minimal maintenance.

- Capable of producing excellent “wet-look” finishes.

- Limited operating time, typically up to 4 hours at a stretch.

Electric:

-

- Simple to operate.

- Quiet with minimal maintenance needs.

- Low initial cost.

- Long operational life.

- Lighter and more compact than propane or battery models, making them easy to store and transport.

- May lack sufficient pressure for achieving the best shine in some cases.

| Floor Pad | Description |

|---|---|

|

Cleaner

For scrubbing or cleaning with rotary or automatic machines at Low Speed 175–600 RPM |

|

Ultra-High-Speed Cleaning

A mild abrasive pad for surface and heavy spray cleaning. For use with machines that operate at 1500 to 2000 rpm |

|

Wet Scrubbing

Heavy Duty wet scrubbing pad to remove surface coat, ground in dirt, and scruff marks. |

|

Heavy Duty Stripping

A very aggressive stripping pad to remove all finish, sealer and contaminants from the floor surface. |

|

Wet or Dry Power Stripping

Designed for use on those hard to strip surfaces caused by complete inattention or erratic care. Quickly removes surface build-up, stripping coatings down to the bare floor in preparation for re-finishing. |

|

Wet Stripping

For use with stripping solution to remove even the toughest heel marks and heavy finish build up. |

|

Buffing

Dry Buffing, spray buffing, or light scrubbing to remove scuff marks or dirt and restore shine. |

|

Ultra-High-Speed Buffing

A mildly aggressive pad for spray and dry buffing procedures. For use with machines that operate at 1500 to 2000 rpm |

|

Dry Polishing

Use for dry polishing to buff away light soil to create a high lustre. |

|

Dry Super Polishing

Use for dry polishing for a high gloss finish. |

|

Burnishing

A Burnishing Pad for use on softer finishes. |

|

Ultra-High-Speed Burnishing

Natural hair blend contains the strength of polyester with the lubricating effect of natural hair fibre. |

|

Ultra-High-Speed Burnishing

Natural hair blend contains a lighter blend of polyester and natural hair fibre. For use on softer polishes. |